product news

How to make the pizza box? the answer is here.

浏览次数 : 2583

作者 : lacey

更新时间 : 2020-01-13 11:59:43

Whether you're a distributor, importer or store owner of pizza box. You've probably placed hundreds of orders for it . But did you really know how your pizza box came out of the factory? Today we will tell you the story behind the box.

Generally speaking, according to the different printing workmanship, the pizza box can be divided into two categories. They are Flexo printing and CMYK printing.

Quick guide of Flexo printing pizza box:

Making artwork---open die-cut template---open print template--- printing on the machine---die-cutting the paper board---finished product--- packing

CMYK Printing pizza box production process: making artwork---make printing film--printing on machine---surface finished---adhive corrugated---die-cutting --finished product----packing

Production process of Flexo Printing:

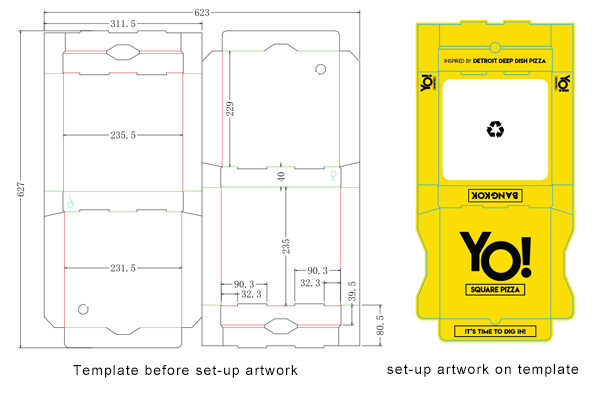

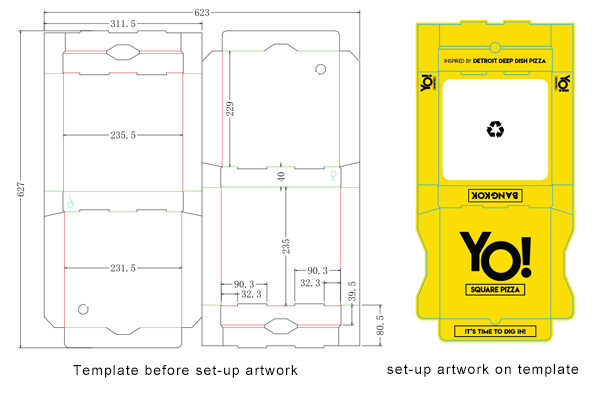

Step 1: confirm template design of the pizza box.

If you already have a template design, that's excellent, it's going to make your purchase faster. But if you don't have, the manufacturer will create for you.

Generally speaking, according to the different printing workmanship, the pizza box can be divided into two categories. They are Flexo printing and CMYK printing.

Quick guide of Flexo printing pizza box:

Making artwork---open die-cut template---open print template--- printing on the machine---die-cutting the paper board---finished product--- packing

CMYK Printing pizza box production process: making artwork---make printing film--printing on machine---surface finished---adhive corrugated---die-cutting --finished product----packing

Production process of Flexo Printing:

Step 1: confirm template design of the pizza box.

If you already have a template design, that's excellent, it's going to make your purchase faster. But if you don't have, the manufacturer will create for you.

Remember, the most important thing when confirm the final design before production, is the text direction CANNOT be put on both sides of the box. As the following picture 1 showed. That should be the correct direction, otherwise,you don’t want your pizza box came out like that way as the below picture 2.

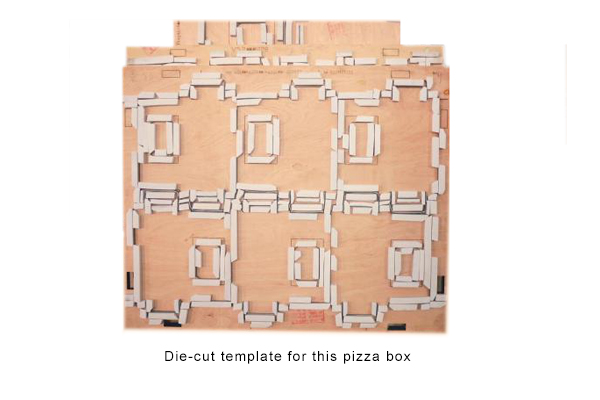

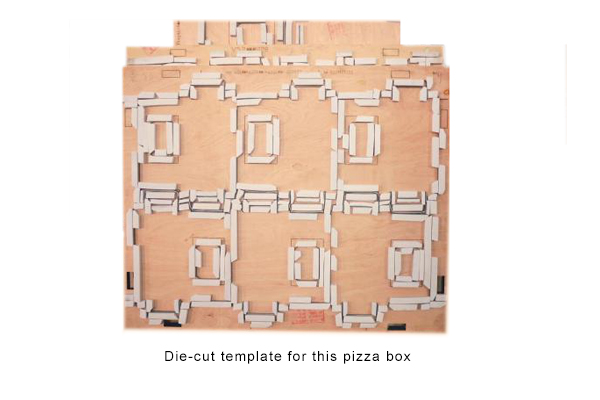

Step 2: open die-cut template

It’s the second step after design confirmed. It’s used for cutting the pizza box on machine.

Normally, the manufacturer will have some regular used die-cut template for selection.

Such as 9”,10”,11”,12”,14” are normal size which demand for a lot. If their existing templates not workable for you, then have to open a new template which usually cost $150.

It’s the second step after design confirmed. It’s used for cutting the pizza box on machine.

Normally, the manufacturer will have some regular used die-cut template for selection.

Such as 9”,10”,11”,12”,14” are normal size which demand for a lot. If their existing templates not workable for you, then have to open a new template which usually cost $150.

Step 3: make print template for the pizza box

At the same time as making die cut template, the print template is also being made.

One template only workable for one color. which means if your design has 3 colors, then need to make 3 templates for your pizza box. Thereout,more colors, higher cost. That’s why flexo printing usually workable for design less than 4 colors.

4: Printing

As soon as the print template finished, will put the template to print the cardboard on the machine.

At the same time as making die cut template, the print template is also being made.

One template only workable for one color. which means if your design has 3 colors, then need to make 3 templates for your pizza box. Thereout,more colors, higher cost. That’s why flexo printing usually workable for design less than 4 colors.

4: Printing

As soon as the print template finished, will put the template to print the cardboard on the machine.

Step 5: die-cutting the printed paper on the machine

After all the cardboard printed the design, it’s time to put them on machine to die-cutting .We have manual die-cutting and full automatic machine.

After all the cardboard printed the design, it’s time to put them on machine to die-cutting .We have manual die-cutting and full automatic machine.

Step 6: After die-cutting, Here come’s the finished pizza box.

Feedback from customers: